Warehouse 4.0 solutions

Logistics

4.0 solutions

Supply Chain

October 9, 2024

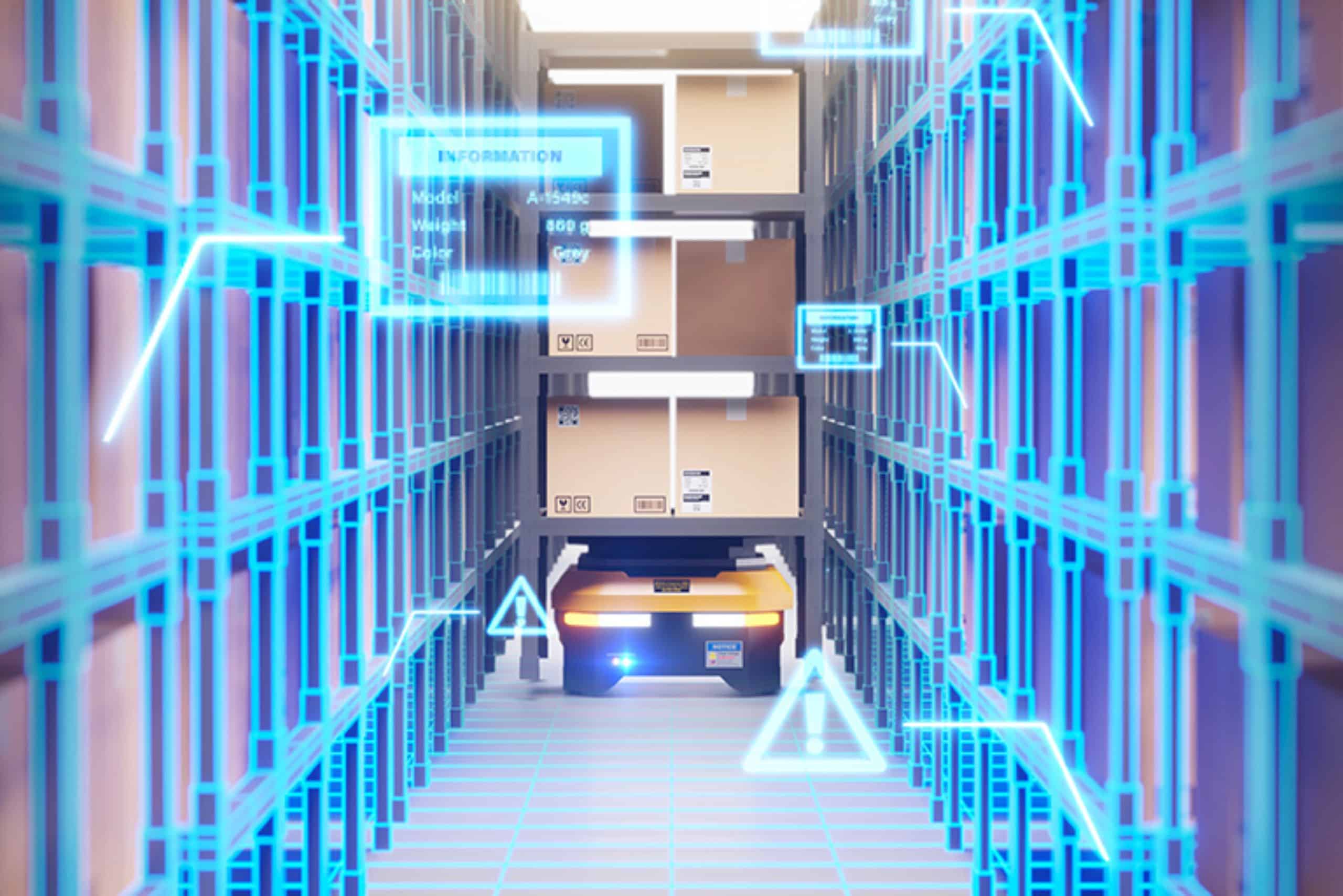

The term “Warehouse 4.0” covers all innovations and connected technologies whose concrete applications increase the performance of the Supply Chain, the personnel who work there and therefore the company which implements them. After the Factory of the Future, the world of logistics is in turn experiencing a revolution thanks to the emergence of new technologies in the field of infrastructure and IT.

So, what innovations and solutions to meet these logistical challenges? And how can these technologies help accelerate changes in companies, both in their profession and in their markets?

What are the challenges for warehouse logistics?

The challenges and issues faced by logistics managers mainly concern:

- Productivity,

- Reduction of error,

- Synchronization,

- The service rate,

- Maintaining stocks

- Management of logistics activities.

To meet these challenges, all warehouse processes are involved. In fact, this does not spare unloading, storage, restocking, preparation, loading, support functions, etc.

Today, new mature and available infra or IT solutions can meet the majority of these challenges.

How can new technologies impact logistics?

Gain productivity

Thanks to new technologies, it is possible to increase inventory productivity by automating counting using RFID readings. It is also entirely possible to increase the productivity of receptions by simplifying access to management and printing solutions, and/or to increase productivity in order preparation by limiting the charging port through 'a direct shipment of the cobot to the packing area. All this, in parallel with the picker who continues his picking activity. Productivity can also be improved by simplifying the identification of the package in which to place the goods to be shipped.

Among the solutions connectable to a WMS, let us cite the Husky intelligent cobot developed by the Nantes company E-Cobot , which can be transformed into a real assistant for operators:

- Picking/kitting,

- Post supply,

- Evacuation of finished products,

- Small logistics train / milk run,

- Kanban management,

- Post to post transfer,

- Transfer to stock/shipping,

- Returns of empty bins,

- Waste disposal,

- Tool transport

Improve inventory quality

Technological solutions can also increase the quality of stock keeping by directing the operator to the drop-off location. The quality of service can also be increased by limiting the number of errors when preparing orders or loading goods.

Among the solutions connectable to a WMS, let us cite the dynamic storage system marketed by the company PTLS (Pick To Light System) indicating where to store the goods in stock.

Synchronize information

Certain technologies can also provide enriched information . For example, this information can relate to the location of preparation carts to allow “accompanied driving” of operators in their daily tasks. It can also provide them with visual information on routes through the warehouse (filming, packing, inspection).

They also make it possible to optimize storage strategies in order to dedicate each operator to their area and limit their movements, and deliver dynamic information on activity indicators. The latter thus unite the teams around common objectives (number of orders prepared, receptions carried out, pallets awaiting storage, etc.). These technologies are also there to limit the administrative tasks of making carrier appointments or those involving the search for evidence in the event of justification of customer or carrier disputes.

The company In Virtus , for example, is developing, using IoT technology, a geolocation system for assets in the warehouse. Also, the company TKH Group specialized in providing video proof in warehouses, and finally the dynamic Shiptify which has developed a real “Doctolib” for making carrier appointments.

Optimize storage and travel

Certain technologies make it possible to analyze the way in which goods are stored and thus assign a better storage strategy to each item based on its properties. The objective here will be to reduce travel when preparing orders or to limit the saturation of picking areas. This will allow them to relocate or restock their products.

Always with the aim of optimizing stocks, some solutions even go so far as to analyze and optimize the replenishment thresholds of a picking stock, at the same time improving the use of surfaces and the number of restocks.

Finally, we could discuss solutions that increase inventory frequencies without increasing the human burden. This makes it possible to increase the quality of stock keeping. The algorithms thus smooth reception activity over the week without impacting resources and without “undressing” the preparation team or the technologies which reduce the number of loading errors. This is all possible by setting up checkpoints to get to the correct aisle and load the correct semi-trailer. Thus, French companies specializing in Artificial Intelligence such as Fieldbox.io have developed algorithms allowing dynamic allocation of locations (slotting).

Most read articles

Logistics

Supply Chain

June 10, 2024

Reverse logistics: our management of product returns

Reverse logistics, or reverse logistics, is a management process that focuses on returning products from the consumer to the manufacturer or distributor.

WMS software

Logistics

Supply Chain

July 3, 2024

Inventory management using WMS software

To master your inventory management, it is imperative to use suitable and efficient inventory management software. With this automation, you can monitor the status of your inventory in real time, allowing you to make informed and rapid decisions to avoid stock-outs or overstocks.

WMS software

Logistics

Supply Chain

June 10, 2024

Warehouse management: why use a WMS?

The use of WMS software is today essential to optimize and manage physical flows and stocks in a logistics warehouse. Each warehouse WMS software integration project is unique and requires in-depth reflection as well as the publication of specifications. Your logistics solution must allow you to have an overall view of your activity and its areas for improvement.