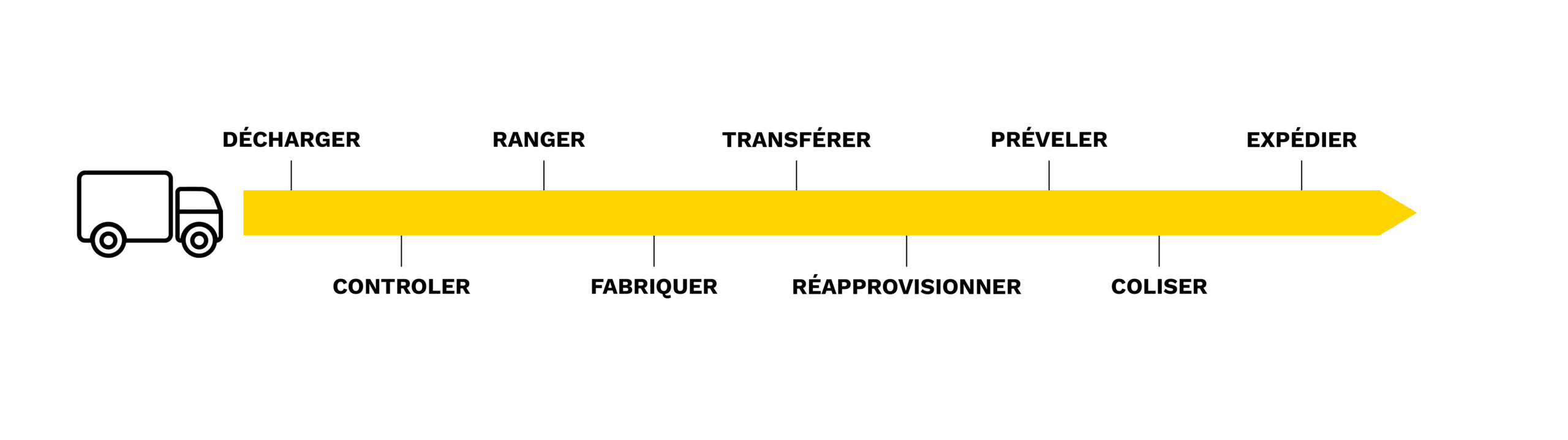

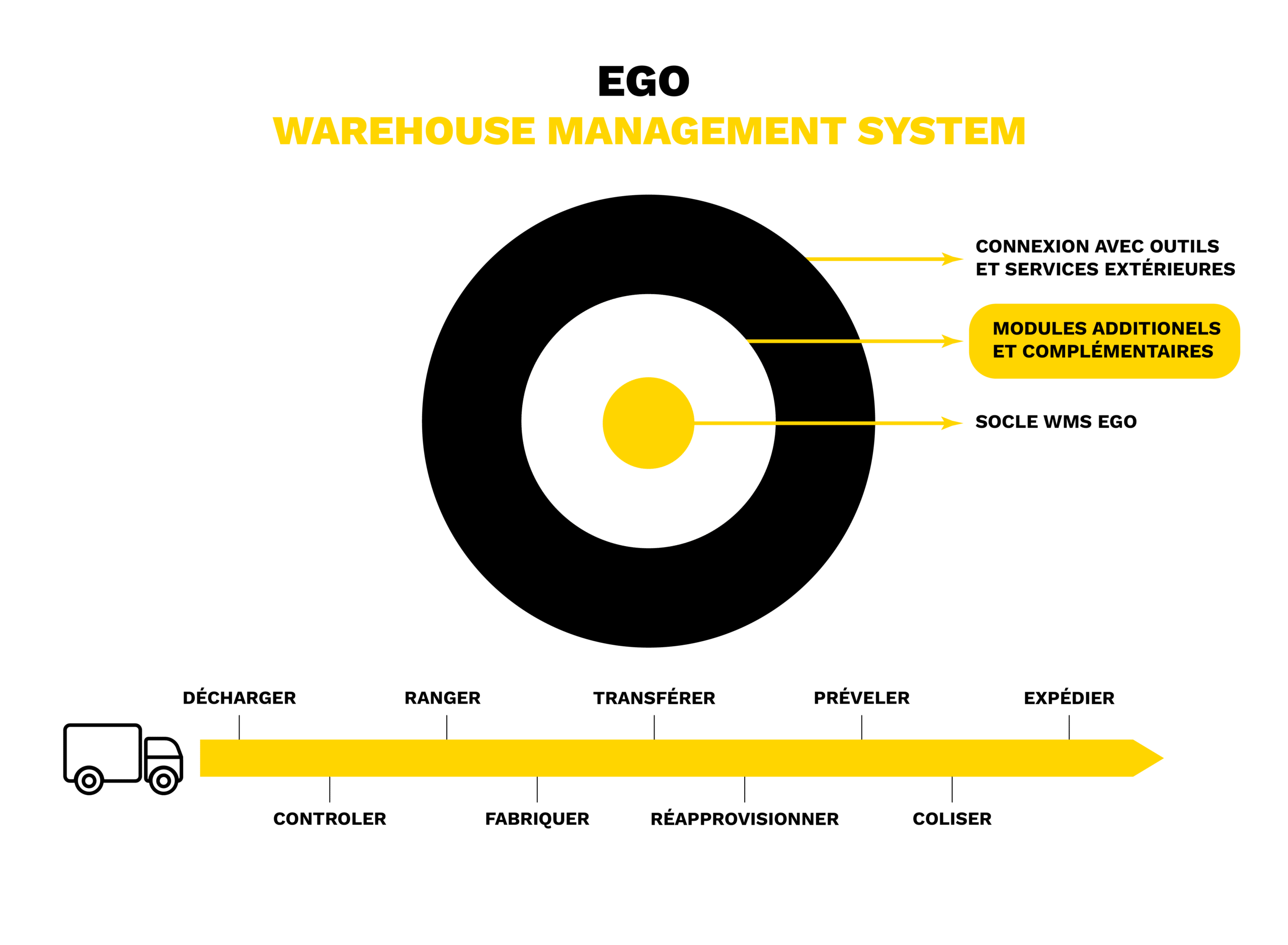

The functionalities and modules of our EGO solution

Features covering all your warehouse activities!

EGO Features

Planning

Management of container tracking, DESADV integration, Entry planning, Load forecasting, Management of delivery announcements,

Management of a pick-up delivery schedule,

Load smoothing.

Functions: DESADV dynamic schedules, load calculation algorithm.

Unloading

Driver reception,

Queue management,

Definition of dock doors,

Unloading and unloading control,

Digitalization of unloading controls,

Digitalization of the CMR.

Functions: Dock management, orphan appointment management, queue management, photo taking, management of tablets and mobile desks.

Reception

Single reference/multi-reference reception,

Management of pallet containers and sub-containers,

Management of logistical variants,

Taking into account batches, DLP, entry deadline,

Management of disputes in reception,

Management of control tasks,

Taking of dimensions, weight and bar code in the reception flow,

Automatic labeling of the units of boxes, bags and pallets,

Identification of goods to be cross-docked and counter-marked.

Functions: Management of containers and sub-containers, multi-typology bar code integration, GS1 compliance, multi-attribute stock management, dynamic labeling and integrated label management, reception on tablet and mobile console, management of multi-operator receptions simultaneous and real time, declaration of disputes with photo taking.

Storage

Automatic addressing under multiple constraints,

Taking rotation classes into account,

Dynamic location management,

Mass management,

Accumulation rack,

“Stackability” management,

Cross-docking with direct docking,

Short-circuiting of the reserve for direct picking,

Pallet storage management and multi-reference trolley storage with optimization of deposits.

Functions: Multi-criteria storage algorithm, dynamic optimization of the algorithm, management of capacity and multiple paths, management of trolleys and machines, consideration of storage constraints, container and cell capacity, management of combined missions.

Production

Management of production deadlines,

Integration of production orders,

Generation of pick lists,

Preparation of pick lists,

Production declaration,

Loss management,

Closure of OFs,

Raw material traceability,

Management of production exit requests,

Declaration consumption.

Functions: Integration of nomenclatures, range management, integration of machine concepts, declaration of losses and consideration of non-de-palletization criteria, ascending and descending traceability based on action log logic.

Inter-site shuttles

Management of inter-site shuttles,

Creation of transfer requests,

Guided preparation of transfer requests,

Docking and loading of shuttles,

Monitoring of shuttle states,

Transit management,

Unloading of shuttles and coupling with addressing.

Functions: Management of shuttles, registration and status, management of shuttle planning and status of shuttles, management of mobile stores, integration of shuttle flows into preparation and storage flows.

Declarative outputs

Management of declarative outputs,

Preparation of declarative outputs,

Management of free outputs,

Management of supplier returns,

Disposal,

Miscellaneous outputs.

Functions: Management of guided and free exits, strategies for managing declarative exits and assessment of declarative exits.

Planning and preparation

Integration of orders,

Integration of delivery orders,

Planning of preparations and smoothing of the load,

Management of a sequencer to automate preparations, reservations and the choice of the most suitable preparation mode,

Management of 12 preparation modes distinct,

Taking into account and calculating pre-packing,

Anticipation of picking replenishments,

Management of criteria for dividing preparation orders according to the areas concerned.

Functions: Planning, load control, sequencer, pre-packing, 12 preparation modes, preparation zone management.

Preparation

Preparation of orders,

Preparation in several stages,

Monitoring the progress of order processing,

Assignment of operator, and multi-criteria operator guidance,

Prioritization of orders to be prepared and management of advanced flow,

Definition of scanning strategies,

Management of processing strategies rupture,

Definition of re-preparation criteria,

Management of criteria for handling backorders.

Functions: Cart management, multi-criteria pushed flow, terminal control console, management of “redeliveries” and backorders.

End of chain

End of line management and preparation control,

Weight control management,

Document management and publishing principles,

Docking and loading management with loading control,

Control of carrier correspondence at the dock during carrier handover ,

Edition of transfer of responsibility documents.

Functions: Integration of weighers, status generator, label generator, conveyor coupling, DESADV, integration of cameras on docks, RFID control gantry, pushed flow in dock power supply.

Replenishment of pickings

Travel management and redevelopment of areas,

Travel under constraints,

Management of re-addressing,

Massification of locations,

Optimization of storage areas,

Identification of underused addresses.

Functions: Management of zone typologies, definition of filling rates, analysis of occupancy rates and “rotation class”/“stock class” crossing.

Moving and Optimizing

Travel management and redevelopment of areas,

Travel under constraints,

Management of re-addressing,

Massification of locations,

Optimization of storage areas,

Identification of under-exploited addresses.

Functions: Management of zone typologies, definition of filling rates, analysis of occupancy rates and “rotation class”/“stock class” crossing.

Inventory management

Management of stock controls,

Management of rotation classes,

Management of reception logistics families,

Addressing,

Preparation,

Replenishment,

Dynamic management of picking replenishment criteria.

Functions: Inheritance management, logistics family management, control function.

Additional and complementary modules

Additional modules

Plan

Planning and management of appointments and expectations:

Appointment making,

Creation of the ASN,

Monitoring and anticipation of charges at reception and the ASN,

Free appointment booking (without order purchase order or ASN).

Yard

Dock management, unloading and allocation of availability:

Yard Management with affection, monitoring and visualization of docks,

Dock management, availability, occupancy rate, release,

Unloading management: launch, monitoring, reception and release of unloading.

Quality

Quality control and unlocking/blocking:

Management of quality control in its 4 dimensions: isolation, blocking, control and sampling,

Blocking, automatic unlocking or conditional on control tasks,

Isolation of goods according to criteria or systematic for implementation available to the quality department,

Management of quality control tasks and monitoring of the results of control tasks for the AQF,

Batch blocking, release of batches and traceability of operations...

Reverse

Management, generation, processing of customer returns (

Reverse logistics ): Processing of customer returns,

Recognition of tracking numbers (transport) and automatic creation of customer returns,

Simplified return search by scanning a medium, of a carrier label, Selection of a delivery, a customer, a date, a shipped item... and multi-criteria cross-checking,

Help with control when receiving the return.

Prod

For production and manufacturing, management of lists to be served, production releases or restocking:

Integration of nomenclatures,

Management of OFs on stock and on demand (Indexed management of OFs),

Automatic creation of lists to be picked,

Automatic generation of production and packaging orders,

Management of production requests,

Production declaration and management of stock reintegration.

Nav

Management of inter-site shuttles:

Creation of shuttle,

Reservation of stock for loading,

Monitoring of the status of the shuttle: Waiting for loading, loading, transit, waiting for unloading, free unloading, etc. Preparation

of shuttles,

Monitoring of inter-site transit,

Unloading of the shuttle with coupling if necessary with addressing.

Guided missions

Management of order preparation missions (push flows vs. pull flows) – approval, scenarios, planning:

Definition of operator authorizations,

Definition of authorized zones,

Criteria for determining priorities,

Definition of control scenarios scan to switch processes to pushed or pulled flows,

Mission planning: Storage, restocking, preparation, consolidation, loading, etc.

STMD

Management of transport and storage documentation for dangerous goods:

Management of storage of dangerous goods,

Definition of authorization thresholds and monitoring of thresholds in real time with generation of blocks and alerts in the event of reaching the thresholds,

Integration of SDS,

Generation of legal reports.

Consumption

Organization of consolidation operations (content and order) at the end of the preparation chain: grouping, palletizing, labeling, control, etc.:

Support grouping,

Labeling,

Weight control,

Product control,

Consolidation,

Sampling,

Editing carrier label,

Assignment of a retention area or dock,

Editing of delivery documentation.

TRM

Carrier coupling, generation of EDI shipping labels, confirmation and EDI returns:

Integration of the carrier's price list,

Multi-criteria automatic assignment of the carrier,

Integration of the transport plan,

Management of special cases: services required, Product constraints, customer constraints...

Pre-invoicing of transport,

Edition of carrier labels,

Generation of EDI transport for shipment confirmation and return of delivery.

PICKADVANCED

Dynamic management of storage , ABC class, zoning and thresholds:

Predictive analysis model of thresholds and replenishment level,

Assistance in defining storage strategies and replenishment strategies,

Management of the sensitivity of the model to of the trend,

Definition of items subject to the threshold,

Forecasting of picking and reserve consumption,

Reassessment of the threshold,

Management of exceptional events and clipping.

Perf

Performance – management and monitoring of productivity, KPI:

Performance by activity, by team and by person, in reception, reconstitution, preparation, consolidation or shipping,

Emulation between operators.

Dashboard

Personalized dashboard:

Choice of control indicators,

Configuration of indicators according to multiple criteria,

Dashboard definition: grouping of indicators with definition of period, granularity, refresh rate, display type, positioning of the graph in the Dashboard, distribution...

Prestlog

Management and invoicing of logistics services:

Management and descriptions of invoicing sections (storage/recovery/picking/packing/relocation/loading),

Management of quotes for contracted and exceptional operations (non-contract),

Validation of quotes ,

Generation of invoices and associated invoicing details,

Generation of an accounting bridge for invoicing and credit notes,

Printing of logistics service invoices.

WORKFLOW

Generation of tasks and emails following an event in particular:

Manual, one-off generation, or automatic trigger,

Creation of associated tasks and process creation,

Track, assign and restart a task,

Sending emails, etc.

WEB

Exchange with merchant websites – e-commerce:

Exchange with platforms: Shopify, PrestaShop, Magento,

Interfacing with marketplaces: Cdiscount, Amazon, Rue du commerce…

Access via the EGO WebService API: consultation of stocks, evolution order status, package tracking.

PORTAL

Carrier portal for smoothing the workload:

Access to an online appointment booking portal,

Definition of capacity per dock by time slot,

Definition of the opening window,

Management of appointment booking reminders: Appointment confirmation.

Connectors

Go to the following page to consult the Sitaci ecosystem partners page.

Click here: http://sitaci.com/notre-solution/partenaires